New to Climate Change?

Carbon Capture

Carbon capture and storage (CCS) refers to a collection of technologies that can help address climate change by reducing carbon dioxide (CO2) emissions. The idea behind CCS is to capture the climate-warming CO2 generated by burning fossil fuels before it is released to the atmosphere. The question is then: What to do with the captured CO2? Most CCS strategies call for the injection of CO2 deep underground. This forms a “closed loop”, where the carbon is extracted from the Earth as fossil fuels and then is returned to the Earth as CO2.

How does CCS work?

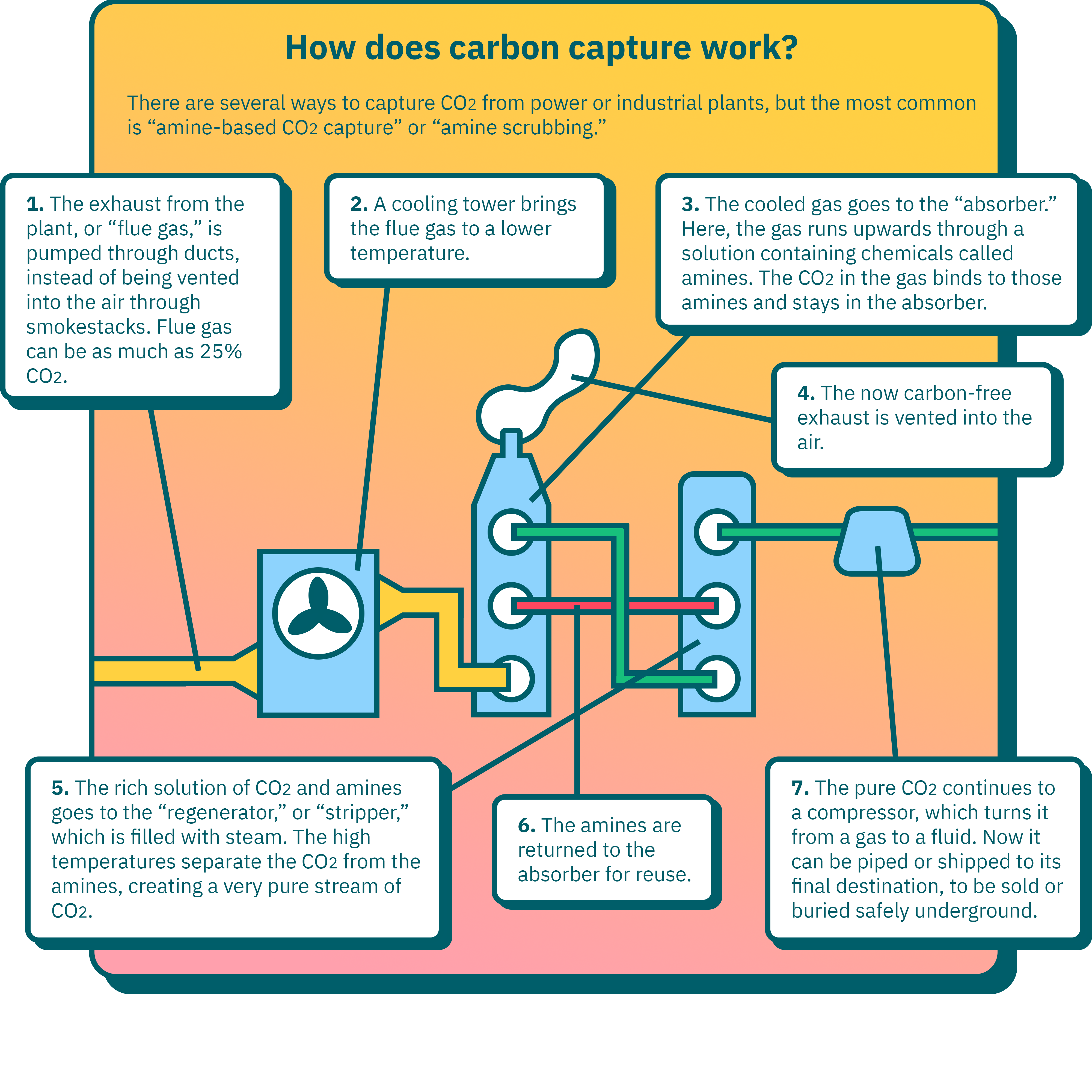

Today, CCS projects are storing over 50 million tons of CO2 every year1: about the amount emitted by a small country like Greece or Peru.2 Capture generally takes place at large stationary sources of CO2, like power plants. Most current carbon capture projects use a liquid to chemically remove the CO2 before it goes out the smokestack, but several new capture processes are under development.

The captured CO2 gas is then compressed so it becomes liquid-like and transported to a storage site, generally through a pipeline. Once at the storage site, the CO2 is pumped more than 2,500 feet down wells into geological formations like used-up oil and gas reservoirs, as well as formations that contain unusable, salty water.

The storage challenge

Choosing the right place to store captured CO2 is important. In the wrong geology, CO2 could escape back to the surface, or the injection process could cause earthquakes. Geologists look for sites with porous rock that large quantities of CO2 can seep into, with a solid “cap rock” above, and where there are no nearby fault lines.

There is no shortage of sites like this, even if we were to use vastly more CCS than we do today. But care must be taken in both injecting and transporting CO2 to minimize risks.

Fortunately, we have a lot of experience with similar challenges. The oil and gas industry maintains millions of miles of pipelines and injects hundreds of billions of gallons of wastewater into the earth each year, a scale that dwarfs CCS today. And unlike oil and gas, CO2 is not toxic or flammable.

Utilization

We emit so much CO2 into the atmosphere that, if carbon capture is going to play any significant part in addressing climate change, we will have to store most of the captured CO2 underground. But “utilization”—selling the CO2 as a valuable product—could help create markets for carbon capture, and make it cheaper for companies to invest in capturing their CO2 emissions.

The main use for CO2 today is enhanced oil recovery: pumping CO2 into oil wells to help flush out hard-to-extract oil. Pure CO2 is also used in greenhouses to grow plants. Most CO2 used for these purposes today is extracted from the earth, but captured CO2 works just as well.

CO2 could also be made into useful products. Companies and labs are working on turning CO2 into plastics, building materials like cement and concrete, fuels, futuristic materials like carbon fibers and graphene, and even household products like baking soda, bleach, antifreeze, inks and paints. Some of these products are already being sold, but none in very large amounts.

Or we could use the CO2 to grow algae or bacteria. This can then be the basis for making biofuels, fertilizers, or animal feed.

Carbon capture economics

Carbon capture has been successfully demonstrated in many industries that produce CO2, including coal power, steel and cement manufacturing, and production of ammonia, ethanol, and other chemicals.1 But simple economics has kept CCS from widespread use. In any industry, adding CCS is an extra cost, and generally a substantial one: In a coal or gas power plant, it has been estimated to as much as double the cost of electricity. While costs may fall with experience, they will not fall to zero.

This means CCS can only compete with government intervention. That could take the form of subsidies for CCS, a carbon tax that charges polluters for the CO2 they put into the atmosphere, or legal limits on how much CO2 industries can emit. In effect, CCS will only be used to the extent we are willing to pay to prevent further climate change.

Where and how CCS might be most useful is hard to predict. In some industries, like cement, CCS is one of the only plausible options for dealing with CO2 emissions. In other sectors, CCS must compete with other mature technologies. Solar and wind power, for example, are plainly cheaper sources of clean electricity than coal or gas with CCS. Yet even here, one can imagine CCS filling a crucial niche. Some other power source must pick up the slack when weather conditions are poor for solar and wind. In the United States today, that is typically gas; in the future, it may be gas with carbon capture.

Capturing CO2 from the air

There has also been considerable interest in using CCS technologies to remove CO2 from the atmosphere, reversing some of the damage we have done to the climate. One option is bioenergy with CCS (BECCS), where biomass (like wood or grasses) removes CO2 from the air through photosynthesis as it grows. The biomass is then harvested and burned in a power plant to produce energy, with the CO2 being captured and stored.

Another option is called direct air capture (DAC). In a typical DAC plant, huge fans funnel air into machines where CO2 is removed using a chemical process. However, the concentration of CO2 in the air is about 300 times less than in a smokestack, making it much less efficient to capture. Because of this, DAC uses a great deal of energy and is quite expensive today.

Our readers have sent in many questions about carbon capture and storage. You can read some of these questions and their answers below:

- How efficient is carbon capture?

- If a fossil fuel plant uses carbon capture, what percent of the energy it makes goes to the CCS equipment?

- What is the risk that captured CO2 will escape again?

- Could pumping CO2 underground have the same negative impacts as fracking?

- Are there risks to transporting CO2 in pipelines?

- How much is captured CO2 worth?

Updated August 8, 2025.

1 According to the Global CCS Institute, an industry-supported think tank which advocates for and collects data on worldwide carbon capture projects. Global CCS Institute: Global Status of CCS 2024.

2 Friedlingstein, Pierre, et al.. "Global Carbon Budget 2024." Earth System Science Data 17 (2025). https://doi.org/10.5194/essd-17-965-2025.