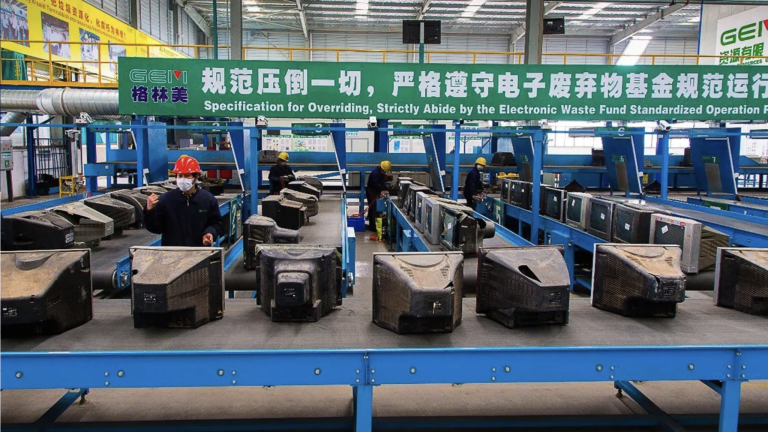

The world of clean tech is built on a lot of minerals—lithium, nickel, cobalt, magnesium, tungsten—that primarily come from mines. But the Chinese recycling company GEM has its eyes on another source: the tons of electronics and batteries that are discarded every day. From factories it calls “urban mines,” GEM breaks down these devices, extracts the minerals, and remakes them into raw materials.

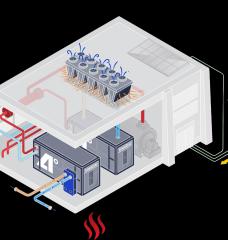

GEM, which stands for Green Eco-Manufacture, was founded in 2001 to recycle small batteries used in everyday items and later began processing all kinds of electronic waste. GEM’s versatile factories can dismantle different kinds of batteries, and its hydrometallurgical extraction techniques are more effective at removing critical materials than competitors’ methods. For example, GEM can recycle over 90% of lithium from used batteries and extract nickel from materials that contain less than 0.1% of the metal. Batteries that still have 60% or more of their original recharging capacity are reused in mopeds or street lamps; the rest are crushed for mineral extraction.

In the past several years, as the number of electric vehicles has surged, the company has found more demand for its technology. According to GEM, it has signed deals with over 650 auto companies and EV battery makers, including Mercedes-Benz and Toyota, to recycle their retired batteries.